I extended my existing 24V AGM lead acid battery bank with BOS LE300 12V smartbattery modules to create an hybrid battery. While the installation is plug & play in a 12V system, some things are to consider to make them work right in a 24V system.

While this is a german blog, I swiss reader asked me to write an english article about my recommended setup of BOS LE300 to extend an existing 24V lead acid battery system.

Please note that this is a recommendation. I do not give any guarantees. But I can say that this setup works fine in my boat for over two years now (as of july 2023).

Step 1: Make Sure That Your 24V Battery Installation is Correct

Building a 24V system out of multiple 12V batteries seems to be simple. But it’s more than wiring 12V blocks in series. In short:

- Make sure you have a midpoint line, with the right cable dimension.

- Make sure the positive and negative lines of each 24V bank (out of two 12V batteries each) have the same length to the vehicle’s power distribution busbars.

If you don’t know what a midpoint line is, or otherwise in doubt, refer to Victron’s excellect manual Wiring Unlimited, section 3.1 (page 15) and section 3.5 (page 19).

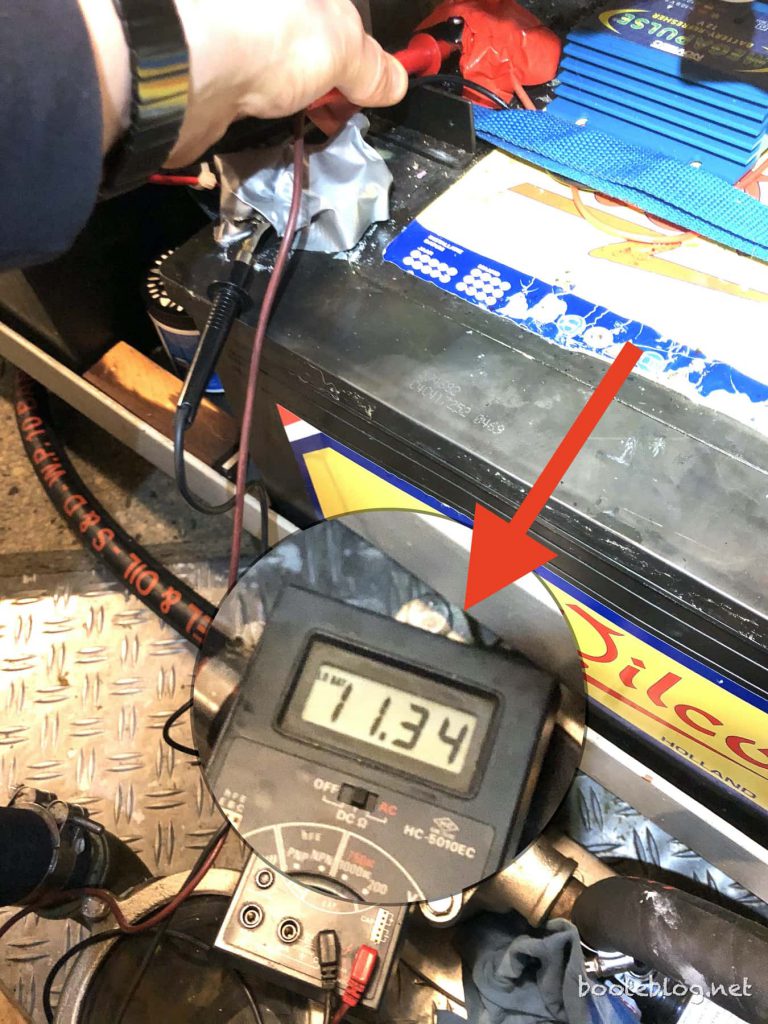

Step 2: Check Voltage of Each Battery

Measure the voltage of each 12V battery in your 24V system while not being charged. Each battery should have more or less the same voltage, you may see a difference of 0.1 to 0.3 volts if you don’t have a battery balancer yet. If the difference is higher, for example 12.7V versus 12.0V, the battery with the low voltage may already be damaged.

If one battery is well below 12V without significant load while the other is well above 12V, the battery with the low voltage is dead. You can proceed with the LE300 installation procedure, and it will help to get much more power out of your system. But nevertheless, if the LE300 modules are empty, the lead acid batteries will provide much less power than they should.

Step 3: Install a Battery Equalizer

In any lead acid 24V system you need a battery equalizer to prevent different states of each battery in the system. For details see Vitron’s Wiring Unlimited, section 3.4, page 18.

While many 24V systems works without an equalizer for a long time, an equalizer is absolutely neccessary when you add LE300 modules: Each LE300 module might change into charging state at slightly different times, which produces voltage imbalance between batteries. Without an equalizer, this will lead to different loading states of each lead acid battery quite fast.

Victron’s equalizer is a passive system, which works with resistance to balance power distribution between the batteries. In my case, this approach was not enough to keep my lead acid AGM batteries in balance. I installed the Loadchamp „active“ equalizer (here a link to Amazon Germany). You should find devices with the same look and functionality from other vendors in your country.

An active equalizer „moves“ power from one 12V battery to the other depending on each battery’s power level. If running wild, such an equalizer might drain a battery, which I never experienced. Nevertheless, checking the voltage of each battery in the system from time to time is a good idea. Or install a battery monitor with is able to measure the midpoint voltage, too, like a Victron BMV.

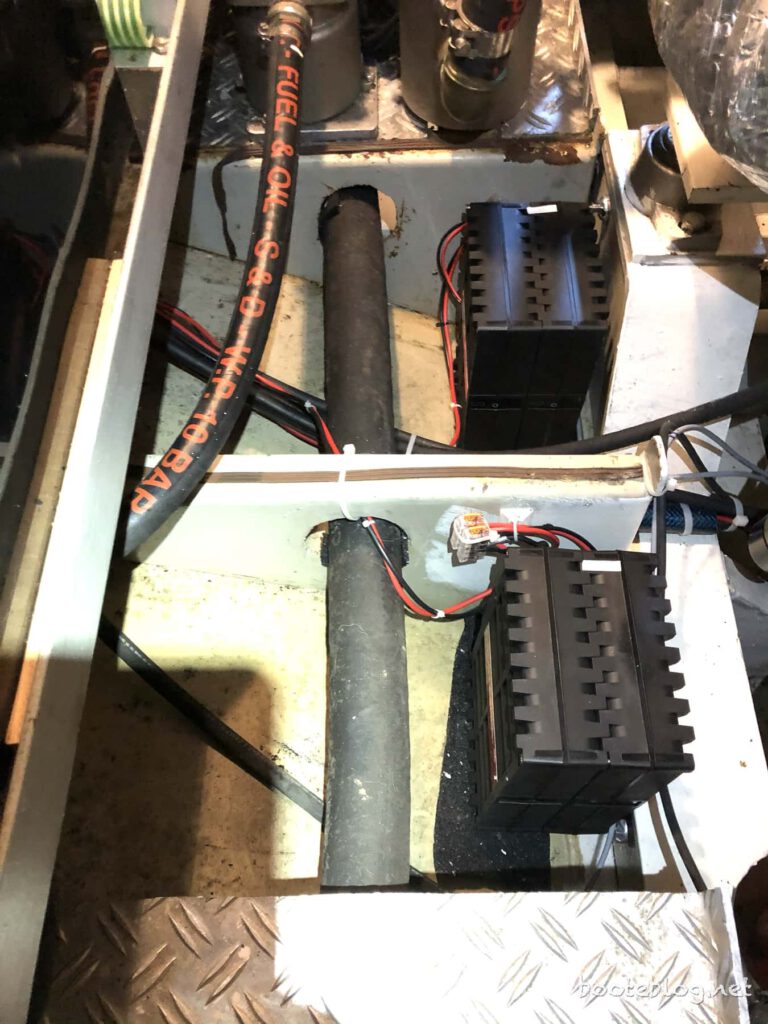

I installed two equalizers in parallel first to have some redundancy. But I found that this is not necessary and might even lead to failure of the equalizers, so I do not recommend it. Now I have two equalizers in place, but only one connected. If one fails, I can disconnect it and connect the spare equalizer very fast.

Step 4: Install LE300 Modules

Measure voltage of each 12V battery again. Since you installed the equalizer, each 12V battery should have nearly the same voltage. If not, wait some days with charging cycles and let the equalizers do their work.

LE300 comes as single module or set of multiple modules. LE300 modules are for 12V batteries, so you need to connect the same number of LE300 modules to each of your 12V lead acid batteries.

If you have a set, they need to have a communication wire between each module. In most cases such wire is pre-installed, but you can combine a number of single LE300 modules to a set by yourself. In that case, make sure you ordered the communication wire(s), too.

Connect the positive and negative wires of each LE300 module in your set to a busbar of some kind. In my case I simply used WAGO terminals (like WAGO 221-415 for five wires). Use the LE300 power cables as they are if possible. If you need to extend them, make sure every cable gets the same length.

Prepare wires from these busbars to each 12V battery with appropriate dimensions to have only minimal voltage drop. Each LE300 puts up to 10A@12V to the wire. So if you have for example a set of 6 x LE300 modules, your wiring needs to be suited for 60A@12V.

Each LE300 module has a breaker of it’s own. Nevertheless, it might be a good idea to install a breaker for the whole set of LE300 modules shortly after the busbar, too. It makes it easier to disconnect the modules if needed.

Switch off any external power that might charge the batteries, and as many consumers as possible to have only minimal load on the battery bank. Then connect each set of LE300 modules to it’s 12V lead acid counterpart, one after the other.

Each LE300 module is delivered with a loading state of 25% or more. Check voltage of each 12V battery again after some minutes, you should see a voltage of above 13 volts, most probably 13.8 volts. That is because the LE300 provide power to the vehicle now.

On each LE300 module itself press and hold the button and you should see the „power is draining“ lights, as explained in the LE300 documentation.

Step 5: After the Initial Installation

Set your charger to a fixed time for the absorption phase if possible instead of an automatic setting (like Victron chargers are set to by default). Set the time of the absorption phase depending on the total capacity of all LE300 modules and the current your charger delivers so that all LE300 modules have the chance to get fully charged.

Check the charging voltage setting on your charger. It should be ~0.4V less (!) than the maximum voltage accepted by your lead acid batteries. As said above, each LE300 set will change into charging state at slightly different times. In that period, a voltage imbalance is put to the system, and a 12V side of the 24V bank might get an high voltage as of: Charging voltage minus 13.8V.

For example: The charger puts 29.2V to the system (14.6V per side), minus 13.8V equals 15.4V which might be seen by one side of the battery bank. This is bad if your lead acid batteries accept a maximum of 14.6V. In this case, set the charger to for example 28.6V (14.3V per side), which leads to a maximum of 14.8V to one side of the battery bank in that imbalance situation, which should be acceptable.

This might cause the lead acid batteries to not get fully charged because their maximum charging voltage is reached only for a brief period. In my experience with AGM batteries that’s not a problem, nevertheless I disconnect my LE300 modules twice a year and put a full charging cycle on the AGMs.

Please note that this imbalance situation normally happens for a short period of time (below a minute) and mostly at the end of the charging process with minimum current.

Run the following tests after installation:

- After a charging cycle check if all LE300 modules are fully charged according (press button and check the lights).

- Then switch off all chargers and put some heavy load on the system. If you have for example 16 x LE300 altogether they are good for about 16 x 10A@12V = 160A@12V = 80A@24V. So up to a current of 80A all power should be delivered by LE300. The voltage should be stable at about 25V or more.

- If you are able to, draw even more current, for example twice the load the LE300 can handle alone. Now the lead acid batteries are delivering a notable amount of that current and the voltage should be lower than in the previous test, but still stable at something like 24.5V or more.

- Draw power so that the LE300 capacity is at about 50%. Switch on your charger and check if all LE300 modules are charging. Wait for the charging cycle to complete, check if all LE300 are fully charged. If not, the absorption phase was too short.

- Draw power so that all LE300 modules are empty. Start a charging cycle, wait until completion, check if all LE300 modules are fully charged. Again, if that’s not the case, the absorption phase was too short.

If you’re through these tests your new hybrid lead acid/LiFePO battery bank should be fully functional and you can enjoy the advantages of more capacity!

F.A.Q.

- Q: „I have battery pulser devices on my lead acid batteries. Do they work in a hybrid battery system with LE300?“

A: Having battery pulser devices in a system with LE300 is neither tested nor recommended. I removed all my pulsers. Since LE300 covers most load, the lead acid batteries are normally charged and therefore the chance for sulfation is very low.